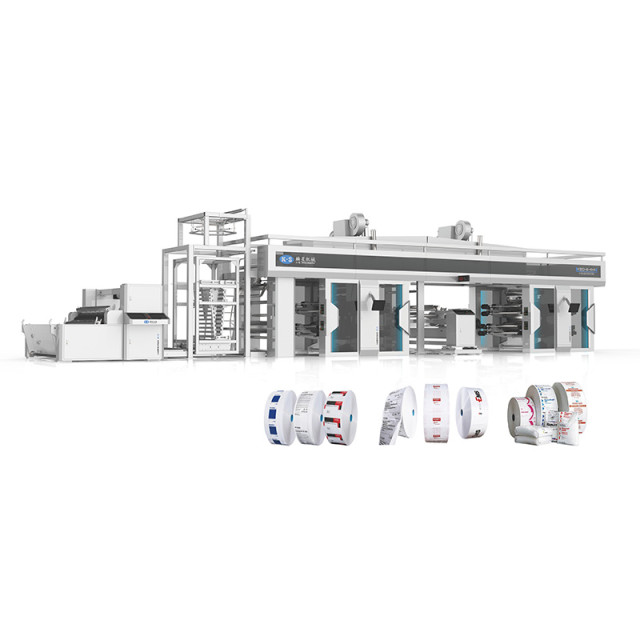

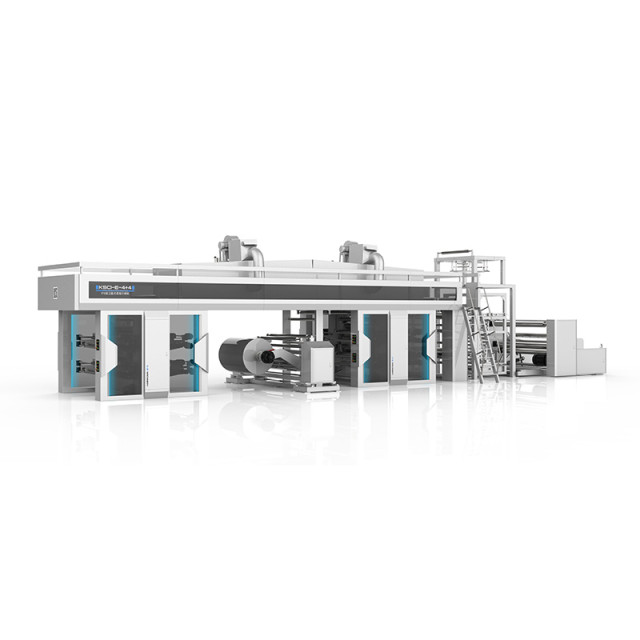

The whole machine adopts PLC and variable frequency drive control system,

The unwinding process of the base material and the end face of the finished product shall be in order to ensure the stability of the winding process;

High precision ceramic anilox roller, fully enclosed doctor blade and pneumatic automatic ink pumping system are used for inking;

The color registration adopts electric registration and pressure control, and the HD color still picture monitoring is convenient for the observation of printing quality;

The unwind adopts high-power corona machine for surface material treatment to strengthen the printing adhesion so that the ink will not fade;

The central drum and central big gear are made of high-precision materials;

Closed loop constant tension design of high-precision tension sensor ensures accurate and stable printing tension

Independent hot air electric heating and drying unit, high efficiency and energy saving, and heat transfer oil or steam heating mode can also be selected;

Adjustable reverse printing frame for reverse color adjustment

The embossing die adopts high-precision alloy abrasives, which has long service life and is not easy to be damaged;

The inserting edge is controlled by stainless steel frame, and the depth can be adjusted manually according to the product size;

The rewinding unit can adopt single work position structure (fully automatic non-stop receiving); 3 "or 6" inflatable shaft loading mode